Insights into Supplier Strategies and Future Opportunities

When it comes to setting the standard in aerospace, few names carry as much weight as Boeing. Recently, a dedicated webinar offered a rare opportunity to hear directly from senior figures within Boeing and UK Government partners about the company’s strategies, its approach to selecting future suppliers, and the challenges shaping the aerospace supply chain.

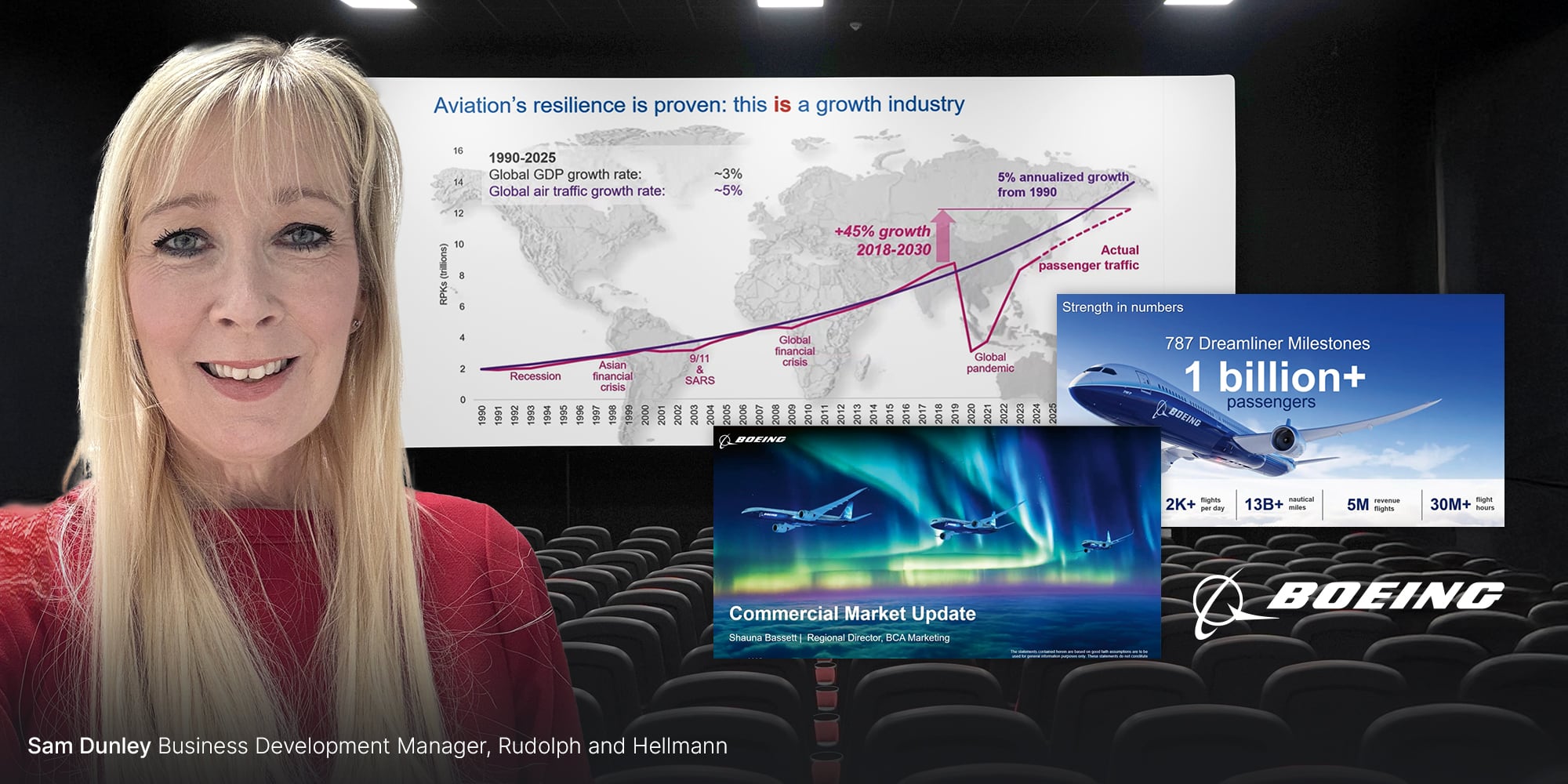

Sam Dunley represented Rudolph and Hellmann at the event. She attended with the aim of deepening the company’s understanding of the aerospace sector and, in particular, the logistical demands of Boeing and its competitors. For a business with a track record in delivering complex logistics solutions, this was an important step towards exploring how our capabilities could support innovation in this demanding industry.

Expert Voices Offering Real Insight

The webinar brought together an impressive line-up of speakers, each bringing a unique perspective on aerospace manufacturing, supply chain strategy, and the opportunities available for UK-based partners. Senior leaders from Boeing, including Wendy Cronie, Senior Director of Supply Chain Strategy & Supplier Development, and David Canada, Director of Strategic Sourcing & Partnerships for Boeing Defence, Space and Security, shared detailed insights into how Boeing evaluates and selects suppliers.

They were joined by Avril Jolliffe, who leads the Boeing Company Strategic Partnership Programme within the UK Government relationship framework, and Jo Bray, Director of Advanced Manufacturing at the Department for Business and Trade, along with other senior figures deeply involved in UK aerospace manufacturing and supplier development. The combination of voices from industry and government ensured that the discussion was not just about Boeing’s needs, but also about the broader economic and policy environment that shapes aerospace opportunities in the UK.

From Manufacturing Stats to Innovation Landscapes

Over the course of the session, the speakers painted a comprehensive picture of the aerospace sector. They examined the current state of UK manufacturing, the support measures in place for the industry, and Boeing’s position across defence, commercial aviation, and global services. They discussed the realities of the supply chain business environment, explored global opportunities for suppliers, and gave a frank account of what Boeing looks for when sourcing new partners—from the technical standards expected to the commercial approach preferred.

There was also a detailed look ahead at the long-term commercial market, alongside an exploration of Boeing’s innovation landscape, which covers everything from advanced production methods and materials to global technology capabilities. Importantly, they also addressed the opportunities within Boeing Global Services, which plays a critical role in supporting the aviation ecosystem throughout the full product lifecycle.

Opportunities for Logistics Innovation

For companies like Rudolph and Hellmann, the session highlighted clear areas where operational logistics could play a vital role. Boeing’s manufacturing and refurbishment functions are complex, time-sensitive, and highly regulated—making logistics excellence a competitive advantage for any supplier. By leveraging our experience in managing high-value, precision supply chains, we can help streamline production workflows, reduce downtime during refurbishment cycles, and create smarter solutions for moving parts and materials through every stage of the aerospace lifecycle.

The emphasis Boeing places on innovation aligns perfectly with our own approach to logistics. Whether through technology-driven tracking systems, efficiency gains in warehouse operations, or sustainable transport solutions, there is significant potential to deliver value in ways that enhance performance while meeting the exacting standards of the aerospace sector.

Looking Ahead

The Boeing webinar was more than an information session—it was a masterclass in how one of the world’s most advanced manufacturers thinks about its supply chain. For Rudolph and Hellmann, it provided valuable knowledge that will help us engage with the aerospace sector in a way that is informed, targeted, and innovation-led. By applying our homegrown timber expertise in operational logistics to aerospace manufacturing and refurbishment, we are well-positioned to contribute solutions that meet both the challenges and ambitions of industry leaders like Boeing.